A Brief History

A Brief History

A Brief History

A Brief History

Finite Element Analysis (FEA) was first developed in 1943 by R. Courant, who utilized the Ritz method of numerical analysis and minimization of variational calculus to obtain approximate solutions to vibration systems. Shortly thereafter, a paper published in 1956 by M. J. Turner, R. W. Clough, H. C. Martin, and L. J. Topp established a broader definition of numerical analysis. The paper centered on the "stiffness and deflection of complex structures".

By the early 70's, FEA was limited to expensive

mainframe computers generally owned by the aeronautics, automotive,

defense, and nuclear industries. Since the rapid decline in the

cost of computers and the phenomenal increase in computing power,

FEA has been developed to an incredible precision. Present day

supercomputers are now able to produce accurate results for all

kinds of parameters.

What is Finite Element Analysis?

FEA consists of a computer model of a material or design that is stressed and analyzed for specific results. It is used in new product design, and existing product refinement. A company is able to verify a proposed design will be able to perform to the client's specifications prior to manufacturing or construction. Modifying an existing product or structure is utilized to qualify the product or structure for a new service condition. In case of structural failure, FEA may be used to help determine the design modifications to meet the new condition.

There are generally two

types of analysis that are used in industry: 2-D modeling, and

3-D modeling. While 2-D modeling conserves simplicity and allows

the analysis to be run on a relatively normal computer, it tends

to yield less accurate results. 3-D modeling, however, produces

more accurate results while sacrificing the ability to run on

all but the fastest computers effectively. Within each of these

modeling schemes, the programmer can insert numerous algorithms

(functions) which may make the system behave linearly or non-linearly.

Linear systems are far less complex and generally do not take

into account plastic deformation. Non-linear systems do account

for plastic deformation, and many also are capable of testing

a material all the way to fracture.

How Does Finite Element Analysis Work?

How Does Finite Element Analysis Work?

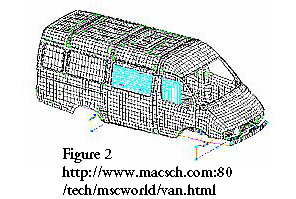

FEA uses a complex system of points called nodes which make a grid called a mesh (Figure 2). This mesh is programmed to contain the material and structural properties which define how the structure will react to certain loading conditions. Nodes are assigned at a certain density throughout the material depending on the anticipated stress levels of a particular area. Regions which will receive large amounts of stress usually have a higher node density than those which experience little or no stress. Points of interest may consist of: fracture point of previously tested material, fillets, corners, complex detail, and high stress areas. The mesh acts like a spider web in that from each node, there extends a mesh element to each of the adjacent nodes. This web of vectors is what carries the material properties to the object, creating many elements. (Theory)

A wide range of objective functions (variables within

the system) are available for minimization or maximization:

There are multiple loading conditions which may be

applied to a system. Next to Figure 3, some examples are shown:

Each FEA program may come with an element library,

or one is constructed over time. Some sample elements are:

Many FEA programs also are equipped with the capability

to use multiple materials within the structure such as:

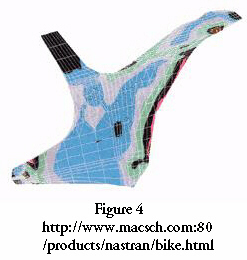

Structural analysis consists of linear and

non-linear models. Linear models use simple parameters and assume

that the material is not plastically deformed. Non-linear models

consist of stressing the material past its elastic capabilities.

The stresses in the material then vary with the amount of deformation

as in Figure 4.

Vibrational analysis is used to test a material

against random vibrations, shock, and impact. Each of these incidences

may act on the natural vibrational frequency of the material which,

in turn, may cause resonance and subsequent failure.

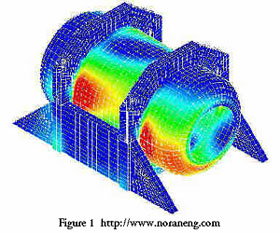

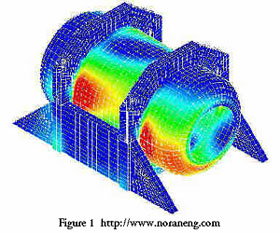

Heat Transfer analysis models the conductivity

or thermal fluid dynamics of the material or structure (Figure

1). This may consist of a steady-state or transient transfer.

Steady-state transfer refers to constant thermoproperties in

the material that yield linear heat diffusion.

Results of Finite Element Analysis

FEA has become a solution to the task of predicting

failure due to unknown stresses by showing problem areas in a

material and allowing designers to see all of the theoretical

stresses within. This method of product design and testing is

far superior to the manufacturing costs which would accrue if

each sample was actually built and tested.

Submitted by Peter Widas

Last updated: 4/8/97

Virginia Tech Material Science and Engineering

Types of Engineering Analysis

Types of Engineering Analysis

Fatigue analysis

helps designers to predict the life of a material or structure

by showing the effects of cyclic loading on the specimen. Such

analysis can show the areas where crack propagation is most likely

to occur. Failure due to fatigue may also show the damage tolerance

of the material (Figure 5).

Fatigue analysis

helps designers to predict the life of a material or structure

by showing the effects of cyclic loading on the specimen. Such

analysis can show the areas where crack propagation is most likely

to occur. Failure due to fatigue may also show the damage tolerance

of the material (Figure 5).