Overview

The concept of fatigue is very simple, when a motion is repeated, the object that is doing the work becomes weak. For example, when you run, your leg and other muscles of your body become weak, not always to the point where you can't move them anymore, but there is a noticeable decrease in quality output. This same principle is seen in materials. Fatigue occurs when a material is subject to alternating stresses, over a long period of time. Examples of where Fatigue may occur are: springs, turbine blades, airplane wings, bridges and bones.

This page will cover the topics included in Materials Science

and Engineering, and Introduction by Callister,

as well as other information that may be helpful to the student

in an introductory materials science class.

There are three common ways in which stresses may be applied:

axial, torsional, and flexural. Examples of these are seen in

Fig. 1.

There are also three stress cycles with which loads may be applied

to the sample. The simplest being the reversed stress cycle

. This is merely a sine wave where the maximum stress and minimum

stress differ by a negative sign. An example of this type of stress

cycle would be in an axle, where every half turn or half period

as in the case of the sine wave, the stress on a point would be

reversed. The most common type of cycle found in engineering applications

is where the maximum stress (smax)and

minimum stress (smin) are

asymmetric (the curve is a sine wave) not equal and opposite.

This type of stress cycle is called repeated stress cycle.

A final type of cycle mode is where stress and frequency vary

randomly. An example of this would be automobile shocks, where

the frequency magnitude of imperfections in the road will produce

varying minimum and maximum stresses.

A very useful way to visualize time to failure for a specific

material is with the S-N curve. The "S-N" means stress

verse cycles to failure, which when plotted uses the stress amplitude,

sa plotted on the vertical

axis and the logarithm of the number of cycles to failure. An

important characteristic to this plot as seen in Fig. 2 is the

fatigue limit.

The significance of the fatigue limit is that if the material

is loaded below this stress, then it will not fail, regardless

of the number of times it is loaded. Material such as aluminum,

copper and magnesium do not show a fatigue limit, therefor they

will fail at any stress and number of cycles. Other important

terms are fatigue strength

and fatigue life.

The stress at which failure occurs for a given number of cycles

is the fatigue strength. The number of cycles required for a material

to fail at a certain stress in fatigue life.

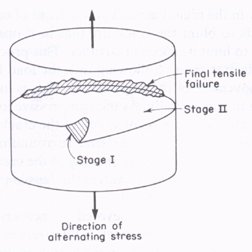

Crack Initiation and Propagation

Failure of a material due to fatigue may be viewed on a microscopic level in three steps:

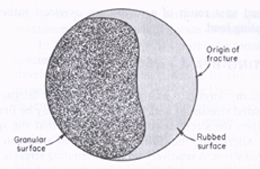

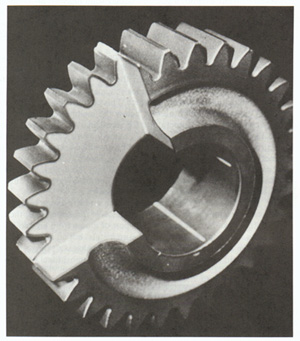

One can determine that a material failed by fatigue by examining

the fracture sight. A fatigue fracture will have two distinct

regions; One being smooth or burnished as a result of the rubbing

of the bottom and top of the crack( steps 1 & 2 ); The second

is granular, due to the rapid failure of the material. These visual

clues may be seen in Fig. 4:

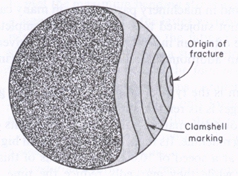

Other features of a fatigue fracture are Beachmarks

and Striations.

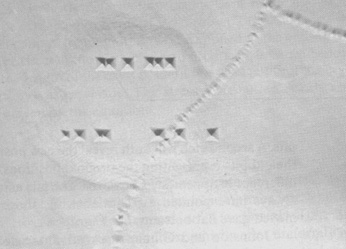

Beachmarks, or clamshell marks, may be seen in fatigue failures

of materials that are used for a period of time, allowed to rest

for an equivalent time period and the loaded again as in factory

usage. Striations are thought to be steps in crack propagation,

were the distance depends on the stress range. Beachmarks may

contain thousands of striations. Visual Examples of Beachmarks

and Striations are seen below in Fig. 5 and 6:

An example of the striations found in fatigue fracture. Each

striation is thought to be the advancement of the crack. There

may be thousands of striations in a beachmark

Demonstration of Crack Propagation Due to Fatigue

The figure above illustrates the various ways in which cracks

are initiated and the stages that occur after they start. This

is extremely important since these cracks will ultimately lead

to failure of the material if not detected and recognized. The

material shown is pulled in tension with a cyclic stress in the

y ,or horizontal, direction. Cracks can be initiated by several

different causes, the three that will be discussed here are nucleating

slip planes, notches. and internal flaws. This figure is an image

map so all the crack types and stages are clickable. For more

information on clickable maps and how to do them see the clickable map tutorial.

Other Useful Links

The rate at which a crack grows has considerable importance in determining the life of a material. The propagation of a crack occurs during the second step of fatigue failure. As a crack begins to propagate, the size of the crack also begins to grow. The rate at which the crack continues to grow depends on the stress level applied. The rate at which a crack grows can be seen mathematically in equation 8.16 in Callister by:

The variables A and m are properties of the material, da is the change in crack length, and dN is the change in the number of cycles. K is the change in the stress intensity factor or by equation 8.17(a & b):

Rearrangement and integration of Eq. 1 gives us the relation of the number of cycles of failure, Nf, to the size of the initial flaw length, ao, and the critical crack length, ac, and Eq. 2:

Factors That Affect Fatigue Life and Solutions

The Mean Stress, discussed in Callister, 8.8, is defined as:

The Mean stress has the affect that as the mean stress is increased, fatigue life decreases. This occurs because the stress applies is greater.

I mentioned previously that scratches and other imperfections on the surface will cause a decrease in the life of a material. Therefore making an effort to reduce these imperfections by reducing sharp corners, eliminating unnecessary drilling and stamping, shot peening, and most of all careful fabrication and handling of the material.

Another Surface treatment is called case hardening, which increases surface hardness and fatigue life. This is achieved by exposing the component to a carbon-rich atmosphere at high temperatures. Carbon diffuses into the material filling interstisties and other vacancies in the material, up to 1 mm in depth.

Exposing a material to high temperatures is another cause of fatigue in materials. Thermal expansion, and contraction will weaken bonds in a material as well as bonds between two different materials. For example, in space shuttle heat shield tiles, the outer covering of silicon tetraboride (SiB4) has a different coefficient of thermal expansion than the Carbon-Carbon Composite. Upon re-entry into the earth's atmosphere, this thermal mismatch will cause the protective covering to weaken, and eventually fail with repeated cycles.

Another environmental affect on a material is chemical attack,

or corrosion. Small pits may form on the surface of the material,

similar to the effect etching has when trying to find dislocations.

This chemical attack on a material can be seen in unprotected

surface of an automobile, whether it be by road salt in the winter

time or exhaust fumes. This problem can be solved by adding protective

coatings to the material to resist chemical attack.

Other Useful Links Dealing With Design Examples

Find: Estimate the maximum tensile stress to yield the fatigue life prescribed

Solution: Use Equations 3 above to solve for Ds.

Eq. 3

Eq. 3

Comments or Questions? Email Shawn Kelly.

1Beer, Ferdinand P, and E. Russell Johnston, Jr. Mechanics of Materials. 2nd ed. New York: McGraw-Hill, Inc. 1992. Images: Fig. 2.54(b), Fig. 3.8(b), Fig. 4.19

Reed-Hill, Robert E, and Reza Abbaschian. Physical Metallurgy Principles. 3rd ed. Boston: PWS Publishing Company, 1994.

The following figures appear in Reed-Hill :

2 Fig. 21.34, page 752

3 Fig. 21.43, page 761

4 Fig. 21.30, page 749

5 Fig. 21.31, page 749

Callister, William D Jr. Materials Science and Engineering, an Introduction. 3rd ed. New York: John Wiley & Sons, Inc., 1994.

The following figures appear in Callister:

6 Figure 8.24, page 209

7 Figure 5.0 , page 89

8 Reed-Hill: Fig. 5.3, page 127

Special thanks to those who provided links:

Chris Meyer, Jireh Yue, Jared Mutter, Ron Halahan, and Matt Gordon

Thanks to Brian Seal for his HTML skillz.

Submitted by Shawn M. Kelly

Virginia Tech Materials Science and Engineering

http://www.sv.vt.edu/classes/MSE2094_NoteBook/97ClassProj/anal/kelly/fatigue.html

Last updated: 5/4/97 04:03:20.43 PM