Finite Element Analysis (FEA) is a numerical method which provides solutions to problems that would otherwise be difficult to obtain. In terms of fracture, FEA most often involves the determination of stress intensity factors. FEA, however, has applications in a much broader range of areas; for example, fluid flow and heat transfer. While this range is growing, one thing will remain the same: the theory of how the method works.

The most efficient method of learning is by example. Therefore, I would like to present to you a simple FEA problem: the case of a three-member truss. The method of solution to this problem should demonstrate the basic concepts of FEA which are present in any analysis.

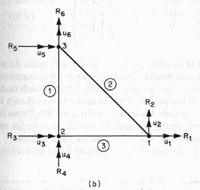

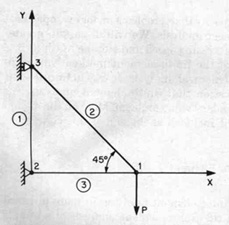

Before introducing specific quantities for our example, let's first take a look at our structure:

The overall objective of our analysis will be to determine the displacements of the truss members given the load P.

The first thing we must do is choose our elements. For our situation this is easy: each truss member should be one element. Further division would accomplish nothing, since each truss member can only support axial loads.

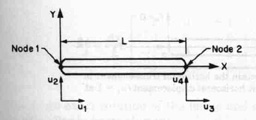

Let us now examine a single truss member:

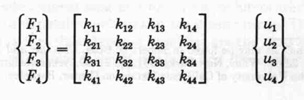

Nodes

are located at each end of the bar, each of which can have

displacements in the x and y directions. The displacements are

denoted u1, u2, u3, and u4.

Corresponding forces due to these displacements are F1,

F2, F3, and F4. The bar has

a uniform cross-sectional area A and Young's Modulus E. The general

relationship between force and displacement is Fi =

kij*uj, where Fi is the force

in direction i, uj is the displacement in direction

j, and kij is the "stiffness" coefficient

relating Fi to uj. In our particular example

of a horizontal truss element, we have the following system of

equations:

F1 = k11u1 + k12u2

+ k13u3 + k14u4

F2 = k21u2 + k22u2

+ k23u3 + k24u4

F3 = k31u1 + k32u2

+ k33u3 + k34u4

F4 = k41u1 + k42u2

+ k43u3 + k44u4

The matrix kij is called the "

stiffness matrix."

It is the matrix which defines the geometric and material properties

of the bar. Stiffness matrices are a fundamental part of FEA.

These matrices always define inherent properties of the system

being studied. For the system at hand, we need to determine the

stiffness matrix. The way we will go about doing this may seem a

little strange at first, but try to follow the reasoning as it does make

sense. Let's begin by assuming u1 = 1 and u2 = u3

= u4 = 0. Then our matrix takes the form:

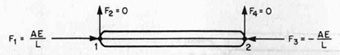

Each force Fi is equal to kj1. Now, recall

from mechanics of materials that the displacement of a rod is

given by u = FL/AE. With displacement u1 = 1, force

1 is F1 = AE/L. To maintain equilibrium, we must also

have a force F3 = -AE/L:

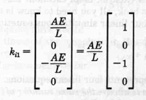

Since our Fi's equal our ki1's, we have:

It important to remember that our element can support only axial

loads. Therefore, displacements u2 and u4

can not give rise to stresses in the bar since these displacements

are perpendicular to the axis of the bar. Thus, the stiffness

coefficients of these displacements must be zero: ki2

= ki4 = 0. Finally, a displacement u3 =

1 will result in forces just opposite to those from u1

= 1, so ki3 = -ki1. Our stiffness matrix is:

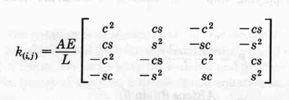

It must be emphasized that the stiffness matrix just derived

is only valid for bars parallel to the x-axis. Through a similar

derivation it can be shown that the stiffness matrix for any bar

oriented at an angle "theta" to the x-axis is:

where c = cos"theta" and s = sin"theta".

Note that when "theta" = 0, this stiffness

matrix reduces to the one we derived for a horizontal bar.

Now knowing the stiffness matrix for any axially loaded bar,

we can apply it to a real situation with specific quantities.

Consider the following truss:

The displacements and external forces are:

Note the symbols we are using: R is an external force on the truss;

F is an internal force resulting from the stresses imposed on

the structure during a displacement. Knowing the orientations

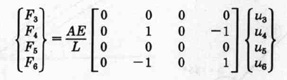

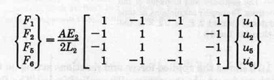

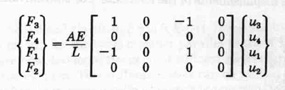

of each element, we can set up matrices for them. Using "theta"

= 90 degrees for element 1, "theta" = 135 degrees for element 2,

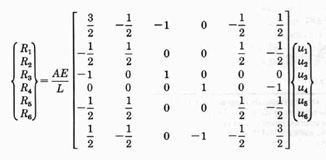

and "theta" = 0 degrees for element 3 we obtain the following matrices:

We can now generate a set of equilibrium equations for each node.

Consider the following figure:

The nodal forces (resulting from element displacements) must be

equal and opposite to the externally applied forces. Note that

we have all forces drawn in positive x and y directions. Thus,

for equilibrium at node 1:

y - direction: R1 - F1(element3) - F1(element2)

= 0

R2 = AE/L ( -u1/2 + u2/2 + u5/2

- u6/2 ).

R4 = AE/L ( u4 - u6 )

R5 = AE/L ( -u1/2 + u2/2 + u5/2

- u6/2 )

R6 = AE/L ( u1/2 - u2/2 - u4

- u5/2 +3u6/2 )

Now recall what we are trying to do here: given a load P, we

want to solve for the displacements at each node. Observing that node 2 is pinned

and that node 3 is on a roller, the displacements u3, u4, and

u5 must equal 0. These values are quite important because without them

we wouldn't be able to solve the problem. As a matter of fact, values such

as these are always needed in finite element analyses; they are

known as "

boundary conditions." Next, we must state the

reactions which are known from our particular loading. We can see from the truss

that R1 = 0, R2 = -P, and R6 = 0.

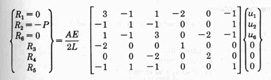

Entering the known displacements and reactions into our

matrix we get:

This matrix reduces to:

We can now finish our problem by solving this matrix for u1,

u2, and u6:

u2 = -4PL/AE

u6 = -PL/AE

For Virginia Tech engineering students interested in FEA, one undergraduate

course is available: ESM 4734 - An Introduction to the Finite Element Method. In

this course, students study the theory and application of FEA to problems

in various fields of engineering and applied sciences. The pre-requisite

for the course is: ESM 2074 - Computational Methods.

References

Finite Element Analysis on Microcomputers, Nicholas M. Baran,

McGraw-Hill Book Company, 1988.

Finite Element Primer, Bruce Irons and Nigel Shrive,

John Wiley & Sons, Inc., 1983.

Submitted by Jason Midkiff

Virginia Tech Materials Science and Engineering

http://www.eng.vt.edu/eng/materials/classes/MSE2094_NoteBook/97ClassProj/num/midkiff/theory.html

Last updated: 4/29/97

(more info. on nodes)

(more info. on nodes)