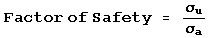

Equation Se-1 [1]. the equation for the factor of safety

Overview:

One of the most important parts of the any engineering design

are the materials that involved in its construction. All materials

have weaknesses and strengths and it is vital that a designer

realize the limitations of certain materials. The purpose of

this section of the fracture web project is to inform MSE 2034

and MSE 2044 students what principle material parameters should

be taken into consideration to prevent or promote fracture. In

addition, this section of the web project will desribe how these

materials can be modified so that they meet necessary design criterion.

Factor of Safety and Fracture Design

All engineers must answer a fundemental question, "How safe

is the design?" An equation, Se-1, is used to express the

safety of a design's mechanical strength as a ratio between the

applied stresses on the materials in the design, and the materials'

yield or tensile strength.

Usually when designing a part, a material's su is replaced

with the material's yield strength, not tensile strength.

This makes good common sense. Most airplanes, for example, can

not afford to have their wings plastically deformed by stresses

and still have the same flight characteristics as before. The value of the factor of safety is also dependent on the application. Fighter jets may have a factor of safety of 1.1, but industrial machinary may have a factor of safety of 3 or higher.

How will the Design Fracture?

What if a material does begin to fail or fractures? Will the

people nearby have time to react? The time interval between the

beginning of failure and total failure is a very important question

in fracture design. There are two primary ways that a material

can fail, ductile fracture, or brittle fracture. In brittle fracture,

the material fails in a quick, catastrophic fashion. Ductile

fracture is little more forgiving. Often there is ample time

to notice crack propagation in a material that fails ductily,

and fix the problem before the materials completely fails. Engineering students you are strongly encouraged to read over

the topics

ductile fracture

and

brittle fracture.

Can the Design be Tested without Destroying It?

Today's engineers now have the ability to model a design in a

computer environment and apply loads to the virtual design. The

standard way of doing this is with a FEA (Finite Element Analysis)

program. Engineering students should take a good look at the section on

FEA

that was developed for this web project to get a better

understanding of how computers can help improve fracture design.

Why do Things Usually Fail?

Most failures occur not because one applied load is too great,

but because a small load is applied repeatedly, this kind of failure

is a result of

fatigue.

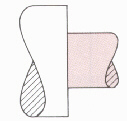

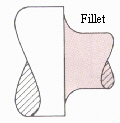

Geometry and Fracture Design:

Not surprisingly, a part's geometry has an impact on its mechanical

performance. The geometry of a part can lead to stress to concentrations.

Mechanical engineers, especially, should beware of stress concentrations

when they design any part, no matter how small. No matter how

strong or tough the material that the part is made of, a poorly

shaped design can have catastrophic consequences. Figures Sf-1

and Sf-2 show two machined pieces. Figure Sf-1 has a sharp end

that create a stress concentration. Figure Sf-2 uses a fillet

instead, minimizing additional stresses on the part.

Figure Sf-2 [1]. Good design will minimize stress concentrations

To learn more about these concentrations the web project has

an entire section set aside for

stress concentrations.

Example Problem : Factor of Safety

A high strength piece of cabling is made from a special alloy,

called Ronkrizite.

(st = 3500 MPa, sy

=2000 MPa). The fiber's diameter is 0.01 m. The load that will

be applied to the cabling is 105 N. What is the factor

of safety?

Answer:

Step 1) Calculate the applied stress.

sa = Load / Area = (105

N) / ( (Pi/4) (0.01 m)2 )

sa = 1270 MPa

Step 2) Assume that the material's yield stress, not tensile stress

should be used in the factor of safety equation. A designer should

always use the yield strength unless told otherwise.

F.S. = su / sa

F.S. = sy / sa

F.S. = 2000 MPa / 1270 MPa

F.S. = 1.57

Submitted by Matt Gordon

Virginia Tech Materials Science and Engineering

http://www.eng.vt.edu/eng/materials/classes/MSE2094_NoteBook/97ClassProj/exper/gordon/www/gordon.html

Last updated: 4/27/97