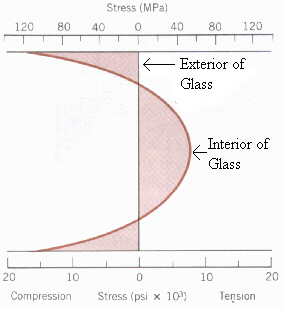

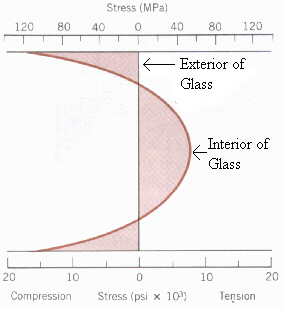

Figure Rf-1 [1]. Tensile and Compressive Stress on Tempered Glass

Overview:

After or during the processing of any piece of material, stresses

may be applied to the material sample. These stresses are used

to help prevent failure of a material. Callister mentions two

examples of this type of fracture design, tempered glass and prestressed

concrete. Tempered glass is glass that has been heated up and

then quenched in an oil bath or cooled in a jet of air. The result

of the semi-rapid cooling process is that the interior of the

glass cools much slower than the outside; which places the exterior

in compression and the interior in tension. A graphical illustration

of the tensial and compressive forces on tempered glass is shown

in figure Rf-1.

Any tensile load must overcome the compressive stresses on the

exterior of the glass first, before the tension placed on the glass can cause it to fail.

The prestressed concrete that Callister mentions works in much

the same way. Concrete, before or after it hardens, has a compressive

load applied to it. Being a ceramic the concrete can easily withstand

the compressive loading without failing. The advantage is that

if a tensile load is ever applied to the prestressed concrete, like the tempered glass,

it would not fail as easily.

Submitted by Matt Gordon

Virginia Tech Materials Science and Engineering

http://www.eng.vt.edu/eng/materials/classes/MSE2094_NoteBook/97ClassProj/exper/gordon/www/gordon.html

Last updated: 4/25/97