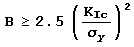

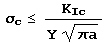

Eq. Te-1 [1]. The minimum thickness of material before plane strain behavior occurs.

Overview:

One of the most important properties of any material for virtually

all design applications is fracture toughness. Given the unusual

units of MPa(m1/2), fracture toughness is a quantitative

way of expressing "a material's resistance to brittle fracture

when a crack is present." [5]. If a material has

a large value of fracture toughness it will probably undergo ductile

fracture. Brittle fracture is very characteristic of materials

with a low fracture toughness value.

Differences between Fracture Toughness:

There are actually four different types of fracture toughness, KC, KIC,

KIIC, and KIIIC.

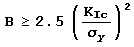

KC

is used to measure a material's fracture toughness

in a sample that has a thickness that is less than some critical

value, B. When the material's thickness is less than B, and stress

is applied, the material is in a state called

plane stress.

The

value of B is given in equation Te-1. A material's thickness is

related to its fracture toughness graphically in figure Tf-1.

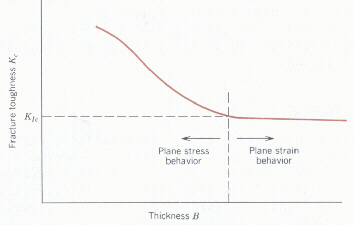

Equation Te-2 shows a material's KC value in relation

to the material's width.

Eq. Te-2 [1]. The fracture toughness of a material with a thickness less than B.

KIC,

KIIC, and KIIIC all represent

a material's fracture toughness when a sample of material has

a thickness greater than B. If a stress is applied to a sample

with a thickness greater than B, it is in a state called plane

strain. The differences between KIC, KIIC,

and KIIIC, however, do not depend on the thickness

of the material. Instead, KIC, KIIC, and

KIIIC are the fracture toughness of a material under

the three different modes of fracture, mode I, mode II, and mode

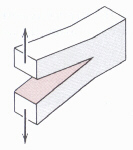

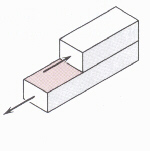

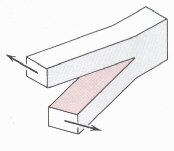

III, respectively. The different modes of fracture I, II, and

III are all graphically expressed in figures Tf-2, Tf-3, and Tf-4.

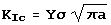

Equation, Te-3 shows how KIC can be calculated knowing

the material's parameters.

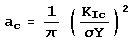

KIC values can be used to help determine critical

lengths given an applied stress; or a critical stress values can

be calculated given a crack length already in the material with

equations Te-4 and Te-5.

Callister provides a table, Table Tt-1, of fracture toughness

of common engineering materials.

Students may notice that the ceramic materials have a much lower

KIC value than the metals. The low KIC

value reflects the fact that ceramic materials are very susceptible

to cracks and undergo

brittle fracture, whereas the metals undergo

ductile fracture.

K1C values are determined experimentally. If you

would like to learn about how these experiments are conducted,

click here on this link.

Example Problem : Fracture Toughness

Plates of a ceramic material called boron carbide are being used

to absorb neutrons in a nuclear reactor. Boron carbide has a

KIC of approximately 4 MPa(m)1/2 and a high

yield strength of 400 MPa. The compressive stresses being applied

to the boron carbide plates, only 10-3 m thin, are

about 5 MPa; Y = 1.1. What is the critical crack length in the

boron carbide plates?

Answer:

Step 1) Are the ceramic plates thick enough to be in plain strain

when a stress is applied to them?

B = 2.5 (KIC / sy)2

B = 2.5 (4 MPa(m)1/2 / 400 MPa)2

B = 2.5*10-4 m

The width of the material is greater than 2.5*10-4 m, therefore plane strain

applies to the problem

Step 2) Plug the known and calculated values into the equation

given and calculate the critical crack length.

ac = (1 / Pi) (4 MPa(m)1/2 /

(5 MPa * 1.1)2

ac = 0.168 m

Submitted by Matt Gordon

Virginia Tech Materials Science and Engineering

http://www.eng.vt.edu/eng/materials/classes/MSE2094_NoteBook/97ClassProj/exper/gordon/www/gordon.html

Last updated: 4/25/97