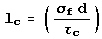

Eq.Pe-1 [1]. The minimum fiber length for a continuous fiber composite

Overview:

Materials can be customized by reinforcing them with rods, fibers,

whiskers, and even large particles of a dissimilar material.

Materials that include such enhancements are called composites.

Composites have two components, a matrix phase and a dispersion phase. The matrix is the material that surrounds the the fibers, or dispersion phase. Steel reinforced concrete is an example of a composite. Concrete is the matrix, reinforced by a dispersion phase, steel rods. The result is a composite material that can handle greater tensile stresses than ordinary concrete can handle alone. (From this point on in the discussion of composites, the dispersion phase will be equivalent with fiber reinforcements.)

A composite works by taking an applied stress and distributing it on the matrix and predominately, on its reinforcements. The result of putting strong fibers into a weak polymer can be a very strong and lightweight material. You may ask, if the fibers are so much stronger than the matrix, why not just use the fibers alone? The answer to that question is simple, design application. There aren't too many parts that are used in industry that can be made of fibers alone. You usually need a solid piece of material in order to build a product. The matrix allows designers to apply the high strength fibers to real-life situations.

Composite materials allow a designer to customize a material so that it will properly cope with the stresses placed upon it. The fundamentals of composite design are based on the materials that are being used for the matrix, and the fibers, the fibers' lengths compared to their diameters, and how the fibers are arranged in the matrix.

Fiber Length:

There is a critical length, lc, that the fibers must

have to strengthen a material to their maximum potential. The

critical length is given in equation Pe-1.

Assuming that the actually length of the fiber is at least 15 times greater than the lc value; the fiber is said to be "continuous"; Otherwise the composite is "discontinous." Generally speaking, continuous fiber composites have superior mechanical properties. Callister states, "short fiber composites can be produce having moduli of elasticity and tensile strengths that approach 90% and 50%, respectively, of their continuous fiber counterparts." [4]

Materials:

There is no practical limit to the number of combinations of

materials that can be used as the reinforcement or matrix in a

composite. Don't get the wrong impression that all composites

are metals in a ceramic matrix, or ceramics in a polymer matrix.

Tables of materials commonly used in the dispersion and matrix

phases of a composites are given in tables Pt-1, and Pt-2.

What's the difference between a whisker, a fiber, and a rod?

The answer is diameter to length ratio. A wire has a relatively

large thickness, probably large enough so that you could pull

out a ruler and measure its diameter. A fiber is much thinner,

and a whisker even more so. In addition, whiskers are single

crystals and by virtue of their extraordinarily small volume are

almost defect free.

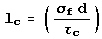

Fiber Alignment and Performance:

Probably the most important consideration that goes into composite

design it aliment of its reinforcing fibers. The fibers is many composites are arranged in one direction;

the fibers are aligned unilaterally. Figure Pf-1 is a graphical

way of representing the strength of a unilateral composite as

a function of the direction of an applied stress. As you can

clearly see, the strength of a composite drops dramatically when

the stress is applied off the alignment of the fibers.

As a future designer you must remember that composite materials

will only give you good performance if the fibers are aligned

to meet the applied stress. There are ways of aligning the fibers

in patterns to compensate for this draw back, but they will not

be covered in this report.

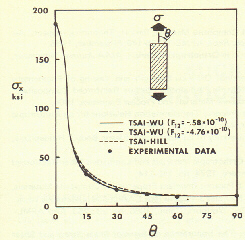

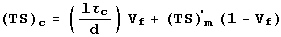

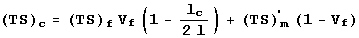

Strength Equations for Discontinous Composites:

Equation Pe-2, and Pe-3 describes the tensile strength of a discontinous

composite material with fibers of length greater than and less

than lc, respectively.

Eq. Pe-3 [1]. The tensile strength of a discontinous fiber composite with fiber length less than lc.

Example Problem : Composite Design

Stresses on the fuselage of a high performance aircraft have

been calculated with an FEA program to be approximately 50 MPa.

Initially designers have been thinking about using a new composite

material called Boloney-ium. Boloney-ium is made from an epoxy

resin (st

= 80 MPa ) and extremely short polymer fibers, called Kanderite, (st

= 2000 MPa). The fibers will make up 30%

of the matrix and have an average length and diameter of 0.25 mm

and 10-6 m respectively. The shear strength between

the fibers and the matrix is very high, approximately 100 MPa. Will the

new composite be able to withstand the applied stress?

Answer:

Step 1) First check to see of the fibers are longer than lc

lc = (st d) /

tc

lc = (2000 MPa) (10-6 m) /

100 MPa

lc = 2*10-5 m

lc = 0.02 mm

The fibers are longer than lc

The fibers' lengths are less than 15lc; therefore

it is a discontinous fiber reinforced composite.

Step 2) Plug the known constants into the equation for the tensile

strength of a discontinously reiforced composite with fibers length

greater than lc and find the tensile strength of the

composite.

(TS) c = (TS)'f Vf ( 1 - (lc

/ 2l ) ) + (TS)' m (1- Vf)

(TS) c = (2000 MPa)*0.3[1 - ( 0.02 mm / (0.25 mm) )] + (80 MPa)' m (1- 0.3)

(TS)c = 608 MPa

(TS)c = 608 MPa

The composite should be able to handle the stress.

Submitted by Matt Gordon

Virginia Tech Materials Science and Engineering

http://www.eng.vt.edu/eng/materials/classes/MSE2094_NoteBook/97ClassProj/exper/gordon/www/gordon.html

Last updated: 4/25/97