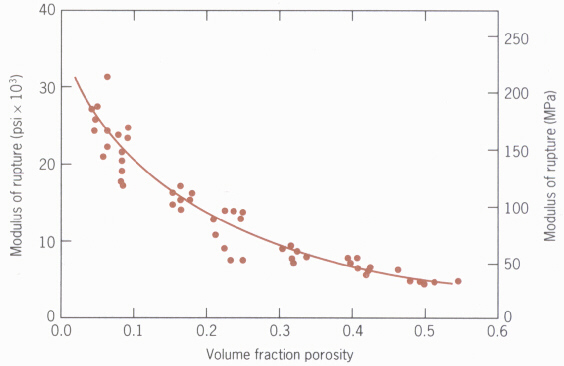

Figure Cf-1 [1]. aluminum oxide's modulus of elasticity as a function of porosity

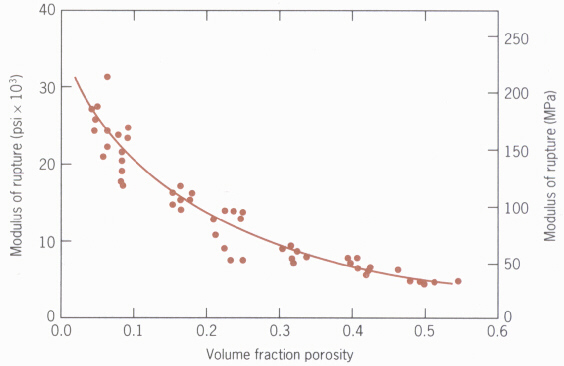

Figure Cf-2 [1]. aluminum oxide's modulus of rupture as a function of porosity

Overview:

Ceramics have interesting design properties. They have excellent

mechanical properties in compression, but are terrible when tensile

loads are applied to them, and are typically very brittle. As a student

in MSE 2034 or 2044, you should be aware not just that ceramics

handle differently in tension or compression, but why this

dissimilarity exists under different types of loading.

The difference between the tensile and compressive performance of a ceramic is caused by the presence of preexisting cracks and flaws in the material. When the material in placed in tension these cracks act as stress amplifiers, which in turn lead create a single dominant crack starting at the tip of a flaw. The dominant crack will quickly cut through the material, ending its life prematurely. In compression, however, the cracks don't behave like stress amplifiers. As a result the ceramic can handle compressive stresses very well.

Since tensile tests conducted on ceramics are difficult to make because of the presence of cracks in the materials, ceramics are exposed to bend tests that measure a parameter of the material called its modulus of rupture. Students in MSE 2044 or MSE 2034 should simply be familiar with the term. I highly recommend that you read over bend testing on page 405 of Callister.

The presence of cracks and defects in the ceramic materials is

called

porosity.

The porosity of a ceramic has a major effect

on a ceramic's modulus of elasticity and modulus of rupture.

In figures Cf-1, and Cf-2 aluminum oxide's modulus and elasticity

and modulus of rupture show, respectively, as a function of porosity.

Figure Cf-2 [1]. aluminum oxide's modulus of rupture as a function of porosity

Improving Ceramics' for Fracture Design:

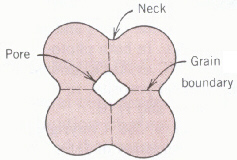

Since the porosity of a ceramic is highly correlated with its mechanical properties, reducing the number of defects in a ceramic is a common way of increasing its strength. The most common way of lowering a ceramic's porosity is sintering.

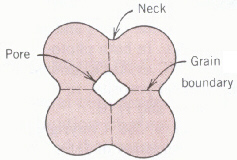

During sintering a ceramic material is heated in a furnace or

oven like device; where it is exposed to high temperatures.

These temperatures depend on the material, but you should know

that they will always be below the melting point of the ceramic.

During the sintering process pores in the ceramic will close

up as seen in the figures Cf-3, Cf-4, and Cf-5.

Figure Cf-4 [1]. During of Sintering

Figure Cf-5 [1]. After of Sintering

Why Sintering Works:

The explanation for why sintering works will be very general

and lacking technical specifics. The following statements break

down the rationale for why porosity decreases during sintering.

Titration:

Another way of decreasing porosity in a ceramic and altering

its mechanical properties is called titration. Titration is not

covered in Callister, but it is an easy concept to grasp. Titration

is immersing a ceramic in a bath of molten material. The molten

material infiltrates the cracks and pores in the ceramic, so that

when the process is complete some or much of the ceramic's porosity

has been replaced by solid pieces of the liquid material.

Working for DARPA (Defense Advanced Research Projects Agency),

Dr. Ihan A. Aksay, and Aleksander J. Pyzik heated a ceramic, boron

carbide, up to 2000oC. At 2000oC the carbide

became very porous, and was submerged in molten aluminum. The

final result of the aluminum titration was a "fully densified

boron carbide-aluminum cerment." The

fracture toughness

of cermert is ranges from 5-7 MPa(m)1/2. While the

cermet is still a brittle material, the titration effectively

doubled boron carbide's fracture toughness of (2-4) MPa(m)1/2.

[3]

Submitted by Matt Gordon

Virginia Tech Materials Science and Engineering

http://www.eng.vt.edu/eng/materials/classes/MSE2094_NoteBook/97ClassProj/exper/gordon/www/gordon.html

Last updated: 4/27/97